Home Improvment

Choosing the Right Fence Post Backfill: Practical Tips for Reliable Installation

Key Takeaways

- Backfill selection plays a critical role in fence stability and durability.

- Different backfill materials offer unique benefits that are suited to specific project needs.

- Proper installation techniques prevent common problems such as leaning or shifting posts.

- Innovations in backfill technology have made installation faster and more eco-friendly.

Why Choosing the Right Backfill Matters

Every sturdy fence starts at the ground level—literally. The type of backfill supporting your fence posts determines not only how long it will last, but also how well it withstands wind, water, and time. A poor choice can result in sagging and instability within just a few seasons or years. Even for do-it-yourselfers, making a smart backfill choice today avoids major repairs in the future—saving time and money when it matters most.

If you’re seeking new and advanced alternatives, the foaming solution for fence post support delivers quick-setting convenience without the weight of concrete. This modern backfill innovation is reshaping projects for homeowners and pros thanks to its blend of strength, ease, and eco-friendliness.

Types of Backfill Material for Fence Posts

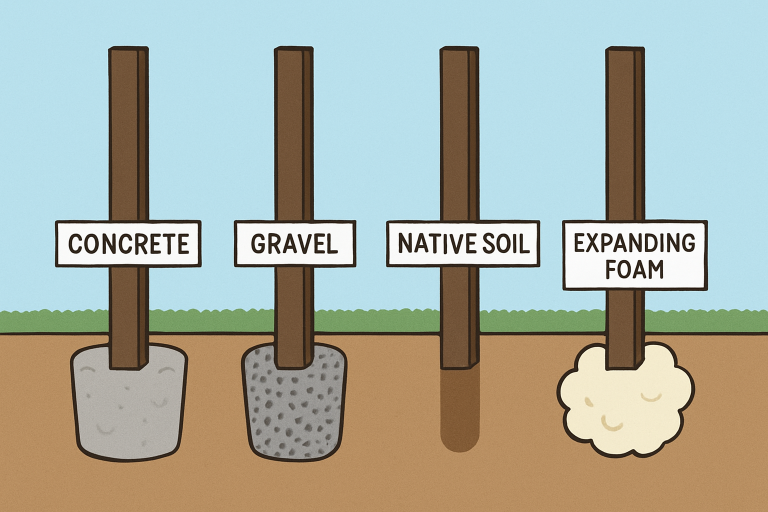

Selecting appropriate materials requires balancing practicality, durability, and the project’s specific requirements. Here’s a breakdown of common backfill choices:

- Concrete: Considered the gold standard for longevity and stability, concrete establishes a rock-solid base. The downside is its weight, mixing time, and less-than-ideal performance in soils prone to water retention.

- Gravel: Offers excellent drainage, reducing the risk of frost heave and post-rot. Gravel is a wise choice for wooden posts and regions with frequent rain, providing stability with minimal settling.

- Native Soil: Best reserved for lightweight or temporary fences. While cost-effective, native earth rarely provides lasting support and is susceptible to shifting with freezing and thawing cycles.

- Expanding Foam: This innovative foam sets rapidly, is surprisingly strong, and is easy to use—even in tight spots. Homeowners seeking speedy, low-labor installations are increasingly opting for this method.

When evaluating which backfill to use, consider climate, your property’s soil type, and the scale and purpose of your fencing. Consulting with local experts or your area’s home improvement center can provide valuable regional-specific advice.

Preparation and Basics: Getting It Right from the Start

Thorough preparation is crucial for the longevity and stability of fence posts. Begin by carefully measuring and marking post locations with string lines and stakes to maintain alignment. Dig holes to an appropriate depth, typically one-third the length of the fence post, to ensure stability against wind and seasonal soil changes.

Clear loose dirt from the hole’s bottom, check for level and plumb, and avoid the temptation to rush this step. Alignment tools, such as levels and plumb bobs, provide the accuracy needed to avoid headaches down the road.

Step-by-Step Installation Guide

- Position and Brace: Set your post plumb and temporarily brace it with stakes for support.

- Add Backfill in Layers: Begin filling the hole in 4 to 6-inch increments. Compact each layer to eliminate air pockets and ensure uniform pressure on the post.

- Check Alignment Frequently: Use a level to guarantee the post remains upright after each layer. Adjust as necessary before the fill fully sets.

- Final Tamping: Once filled, firmly tamp the top layer or follow the manufacturer’s instructions for materials like expanding foam.

- Inspect and Adjust: Make any final alignment adjustments while the materials are still workable for a professional-looking result.

Trends in Fence Post Backfill Technology

The fencing world has embraced several technological advancements, making installations stronger and easier than ever. Innovations like expanding foams—previously used primarily in commercial work—are now accessible to homeowners seeking less mess and faster installs. These products, such as the increasingly popular foaming solution for fence post support, limit carbon footprint and reduce the volume of heavy material transported to job sites. Green initiatives are prompting the development of new, biodegradable options, broadening the choices for eco-conscious consumers.

Conclusion

The success of any fence project hinges on careful planning, proper preparation, and selecting the right backfill material. Whether you choose traditional options, such as concrete and gravel, or modern solutions, like expanding foam, each choice carries implications for stability, durability, and ease of installation. By understanding your soil, climate, and project goals—and following precise installation steps—you can ensure your fence remains secure, aligned, and long-lasting. Embracing new technologies and eco-friendly materials further enhances efficiency while supporting sustainable practices, making today’s fence installations stronger, smarter, and more reliable than ever.