Tech

Grit to Gloss: Navigating the World of Stainless Steel Finishes for Industrial Excellence

Introduction

When selecting stainless steel for industrial applications, both finish and grade fundamentally impact performance, durability, and corrosion resistance. Among the wide array of options, 316 stainless steel stands out for its balance of strength, corrosion resistance, and versatility, all of which are influenced further by the surface finish chosen. The finish not only determines aesthetic qualities but also plays a crucial role in ensuring longevity and ease of maintenance in challenging industrial environments. Selecting the right finish for stainless steel components is vital for optimal performance, extending product lifespan, enhancing hygiene, and minimizing maintenance costs. This balance between protection, functionality, and visual appeal is essential in sectors like chemical processing and food manufacturing.

Understanding Stainless Steel Finishes

Stainless steel finishes are specialized surface treatments created during manufacturing, modifying the material’s texture, reflectivity, and microstructural composition, influencing corrosion resistance and wear tolerance. These finishes protect and enhance the base metal, suitable for various applications. Techniques like hot rolling, cold rolling, pickling, and polishing determine surface characteristics, ensuring cleanliness, durability, and compliance with industrial hygiene and regulatory standards.

Common Industrial Finishes

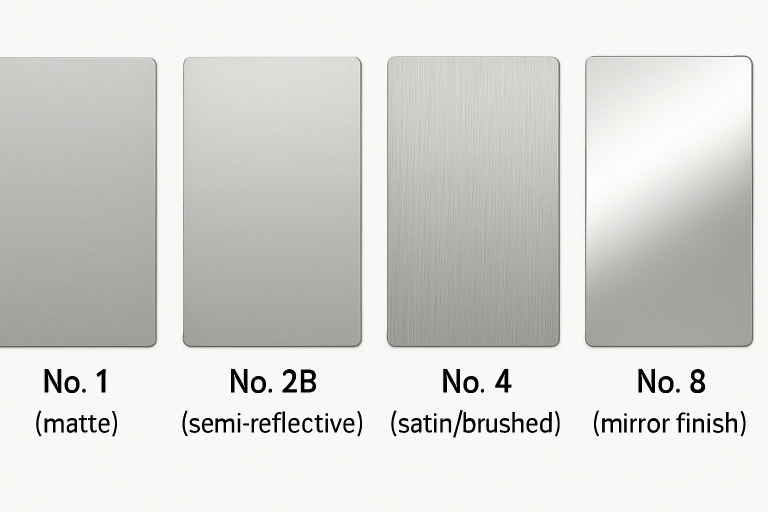

The most prevalent stainless steel finishes in industrial settings each possess their own unique set of features tailored for functionality and appearance:

- No. 1 Finish: Produced through hot rolling, annealing, and pickling, this finish results in a rough, matte surface. It is commonly specified for structural applications or fabrication where the steel will be further processed, and where appearance is of secondary importance.

- No. 2B Finish: Created through cold rolling, annealing, and pickling, followed by a final light rolling pass. This yields a smooth, semi-reflective surface, widely used in industries that require both form and function, such as chemical, pharmaceutical, and food equipment manufacturing. No. 2B finish is easy to clean and provides a higher level of corrosion resistance thanks to its smoothness, making it broadly suitable across industrial environments.

- No. 4 Finish: Achieved via brushing the surface, which leaves a uniform grain and a satin-like appearance. Commonly applied in commercial kitchens, food service equipment, and architectural features, it balances hygienic properties with a visually pleasing look. Its non-directional grain also masks minor scratches, helping equipment maintain an attractive appearance over time.

- No. 8 Finish: Also known as mirror finish, this highly polished surface is largely decorative, found in applications that demand superior aesthetics as well as corrosion resistance. No. 8 is frequently specified in building lobbies, elevators, and high-visibility structures, where appearance is paramount and contamination must be avoided.

Factors Influencing Finish Selection

To achieve peak operational outcomes, it’s crucial to select the right finish based on several influencing factors:

- Corrosion Resistance: Finishes with smoother surfaces, such as No. 2B or No. 8, offer increased resistance by minimizing crevices where contaminants could accumulate. This is particularly relevant for applications where the material will come into contact with harsh chemicals, saltwater, or sanitation agents.

- Aesthetic Requirements: For situations where visible surfaces impact brand perception or user experience, brushed or highly polished finishes provide the necessary visual appeal. In public-facing infrastructure or consumer goods, selecting a finish that enhances appearance can add considerable value.

- Maintenance Needs: Highly reflective or smooth finishes may show fingerprints, stains, or scratches more readily, meaning they could require more frequent or specialized cleaning. Conversely, matte or brushed finishes like No. 4 are more forgiving in high-traffic or rough environments.

- Environmental Conditions: When exposed to severe environments, such as marine atmospheres or industrial chemicals, finishes must be robust enough to protect the underlying steel. Specialized coatings or specific finishes may be chosen to counteract potential damage or accelerate cleaning processes.